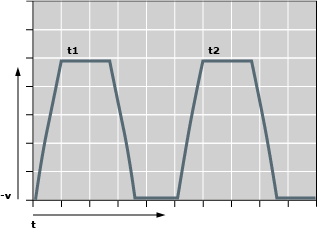

It is important to consider the type of operation. Intermittent operation, with long stoppage times between loadings, influences the build up of a lubrication film in the slide bearing.

The friction is always greatest at the moment of starting, before a lubrication film has time to build up. Therefore, it is important where possible to try to keep down the number of starts since this influence the lifetime of the bearing much more than normal operation.

In order to make this phenomenon less destructive for the bearing, D&E has products with inbuilt lubrication reservoirs. The reservoirs build up during operation and remain in place during the stoppage. In this way, the start friction is significantly reduced and thus the bearing’s lifetime lengthened.

Operating Environment

The bearing’s operating environment is a decisive factor when it comes to the lifetime. It isusual to grade the ”dirt scale” from dust, fibres to sand. The more aggressive the particles are,the more the slide bearing’s sliding surface will be affected, concerning both friction and operatingtemperature.

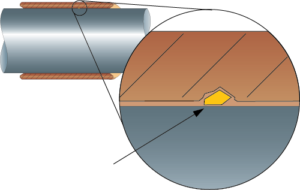

The phenomenon that can arise is calledabrasive wear. The abrasive elementis normally constituted of sandgrains and other foreign particles. Theparticles end up between the bearingsurface and the opposing rotary partand function like sandpaper, as theyare harder than the surface. Whatthus arises is a three-body abrasion.See the figure below.

The phenomenon that can arise is calledabrasive wear. The abrasive elementis normally constituted of sandgrains and other foreign particles. Theparticles end up between the bearingsurface and the opposing rotary partand function like sandpaper, as theyare harder than the surface. Whatthus arises is a three-body abrasion.See the figure below.

Three-body abrasion

Naturally D&E have thought about this and offer slide bearings that are especially resistant tovery dirty environments. Please contact us for more information.