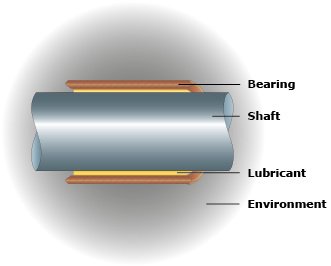

In the tribological system, the lubrication and the surrounding environment (air, gas, salt water,dust etc.) are just as important as the bearing and shaft material. The surrounding environmentcannot usually be controlled, but we can do this for the lubrication.

Lubrication improves the sliding characteristics and gives the following advantages:

- Longer life

- Protection against corrosion on the shaft

- Protection against dust and dirt

- Reduce friction

- Reduce heat production

Recommended lubricants for slide bearings:

- Lithium based greases for standard applications

- Lithium based greases with additives for non-standard applications

- Solid lubrication bodies for maintenance free operation within a determined time period

- Special oils for closed systems

Lubricant additives can also have negative effects if used wrongly:

MoS2

Not to be recommended if the movement is minimal or rare. The grease thickens and MoS2particles gradually block the lubricant groove. The bearing’s lubrication becomes insufficientor impossible. When using bronze materials it is important to consider the sulphur content ofMoS2, which combined with copper forms copper sulphate, which increases wear.

Grafit

Only to be used for shafts with rotary movements. During oscillatory movements, there is a riskthat the graphite forms ”walls”, which results in the shaft’s movement becomes sluggish andharsh.