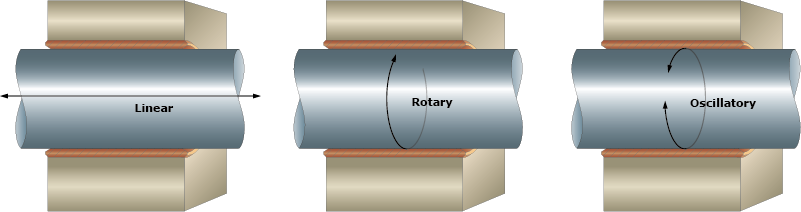

A shaft’s motion can be either rotary or linear or a combination of these. The rotary motion canbe pure rotation or oscillatory. See the figure below for an illustration.

An oscillatory motion is considered to be the most demanding movement, due to the start andstop in every cycle. The lubricant film is exposed to rupture. Fatigue and wear of the slidingsurface increases, which results in an increased quantity of wear particles in the bearingsystem.

Ball bearings, which are primarily designed for rotary movements, have very little contact surface, which causes extremely high strains on the load supporting surfaces. They are therefore unsuitable for oscillatory movements. Therefore, bearings with large contact surfaces are considered generally better and are preferred for such an application.

Our self-lubricating bearings are, in most cases, suitable for oscillatory motions as they have atough sliding surface that generates very few wear particles.

It is important when considering designs including slide bearings that the sliding velocityaffects the temperature rise more than the load.