Benefit from stable bearings with the best lifetime!

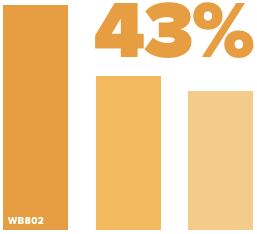

The advantages of WB8 D&E bronze bearings compared to our closest competitor, according to independent analyses.

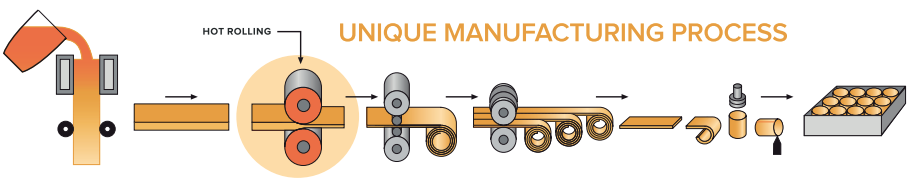

100% TIGHTER MICROSTRUCTURE WITH HOT ROLLING |

The WB8 series features more comprehensive material processing stages, and is at least |

|

LONGER LIFETIME & LOWER RISKA 43% longer lifetime has been demonstrated in third-party lifetime testing. D&E has conducted technical analyses for more than 50 years, and – together with Wieland Werke in German and our industry-leading customers – has developed a pioneering bronze bearing, manufactured with 100% material verification via internal raw material production and processing. |

|

WB802-T-bearings are intended for radial and axial movements in constructions where exceptional long lubrication intervals are wanted.

The bearings are wrapped of a coldformable homogenous bronze, which because of this will obtain exceptional material properties. The standard sizes are fitted with holes, which are dispersed in a special way over the whole bearing-surface. These holes serve as lubricant reservoirs i.a. to rapidly build up a lubrication film in the moment of start and there-with reduce the start friction.

The properties of the WB802-material, together with the procedure of wrapping and calibration, make this type of bearing especially suitable for constructions, where high loads and relatively slow movements are occurring.

Technical data

| Material: | Homogeneous bronze (Cu 91,3%, Sn 8,5%, P 0,2%) |

| Yield point: (Rp0,2) | ca 300 N/mm2 |

| Tensil strenght: (Rm ) | ca 450 N/mm2 |

| Hardness: | ca 125-150 HB |

| Friction: | 0,08–0,25 µ |

| Max speed: | 2,5 m/s |

| Temperature range: | -100 / +200 °C |

| Load | Speed |

| Ca: 280 N/mm2 | 0 m/s |

| 80 – 120 N/mm2 | 0,01 m/s |

| 30 – 40 N/mm2 | 2,0 m/s |

Tolerances: Bearings pressed into housing H7 get tolerance H9. Recommended tolerance for the shaft IT 7 or IT 8 with position of tolerance e or f.

Lubrication: Additional lubrication ought to be done through the shafts or radial through the housings. All customary greases can be used e.g. greases with additives of graphite or molybdenum-disulphide.