Benefit from stable bearings with the best lifetime!

The advantages of WB8 D&E bronze bearings compared to our closest competitor, according to independent analyses.

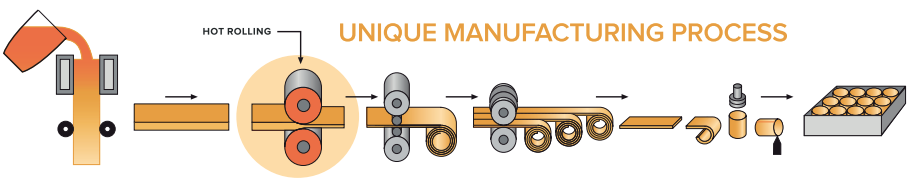

100% TIGHTER MICROSTRUCTURE WITH HOT ROLLING |

The WB8 series features more comprehensive material processing stages, and is at least |

|

LONGER LIFETIME & LOWER RISKA 43% longer lifetime has been demonstrated in third-party lifetime testing. D&E has conducted technical analyses for more than 50 years, and – together with Wieland Werke in German and our industry-leading customers – has developed a pioneering bronze bearing, manufactured with 100% material verification via internal raw material production and processing. |

|

WB800-bearings with or without flange are intended for radial and axial movements.

The bearings are wrapped of a coldformable homogenous bronze, which because of this will obtain exceptional material properties. The execution of the flange permits that the bearing also can carry axial loads.

The standard sizes are fitted with diamond-shaped lubrication indents on the bearing-surface. These indents serve as lubricant reservoirs i.a. to rapidly build up a lubrication film in the moment of start and therewith reduce the start friction. The properties of the WB800-material, together with the procedure of wrapping and calibration, make this type of bearing especially suitable for constructions, where high loads and relatively slow movements are occurring.

Technical data

| Material: | Homogeneous bronze (Cu 91,3%, Sn 8,5%, P 0,2%) |

| Yield point: (Rp0,2): | ca 300 N/mm2 |

| Tensile strenght:(Rm ) | ca 450 N/mm2 |

| Hardness: | ca 125-150 HB |

| Friction: | 0,08–0,25 µ |

| Max speed: | 2,5 m/s |

| Temperature: | -100 / +200 °C |

| Load | Speed |

| Ca: 280 N/mm2 | 0 m/s |

| 80 – 120 N/mm2 | 0,01 m/s |

| 30 – 40 N/mm2 | 2,0 m/s |