A radial slide bearing’s clearence constitutes the difference between the bearing’s internal diameterand the shaft’s diameter. During hydrodynamic operating conditions, the clearence is directlydecisive for the forming of the oil film. It is the function of the oil film to separate the shaft and thebearing surface from each other, so that metal contact is avoided.

Another purpose of the clearence is to accommodate changes in geometry, which can be theconsequence of an increased or reduced temperature in the surroundings. It is not so unusualthat the shaft expands more than the bearing during increases in temperature. The causes reducedclearence.

Another purpose of the clearence is to accommodate changes in geometry, which can be theconsequence of an increased or reduced temperature in the surroundings. It is not so unusualthat the shaft expands more than the bearing during increases in temperature. The causes reducedclearence.

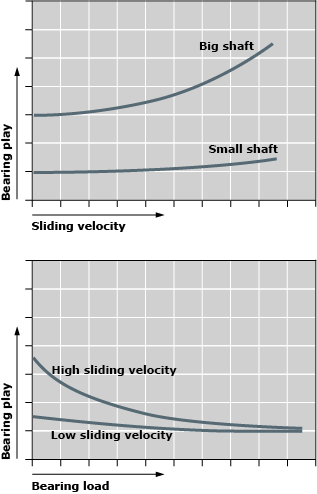

Generally, for high loaded, slowlymoving bearings a small clearenceis chosen. For bearings that havelight loads and move rapidly alarger clearence is chosen. Fromexperience, 0.3 – 5 ‰ of the shaftdiameter is recommended. See thefigure below for the dependence ofthe bearing clearence of the slidingvelocity.

According to previous reasoning,the clearence is dependent on boththe load and the sliding velocity.Other parameters that affect theplay are, for example, the type oflubricant and the operating temperature.The figures below illustratethe bearing clearence dependenceon the loading. At the same time,the sliding velocity is affected.